In the modern world of manufacturing, Computer Numerical Control (CNC) machines have revolutionized the way parts and products are made. Whether it’s producing complex components or simple parts, CNC technology plays an essential role in today’s industries. We offer top-tier CNC services, specializing in both turning and milling. Our focus is on delivering high-quality parts with precision, efficiency, and cost-effectiveness, particularly for medium to large production volumes.

Our services cover the processing of a wide range of materials such as aluminium, steel, copper, brass, and plastics, ensuring that your project is completed with the best materials suited for the job. With the perfect balance of service quality and affordability, we are your go-to source for production runs starting from 100 units per series and 1,000 units annually.

Table of Contents

ToggleWhat is CNC Turning and Milling?

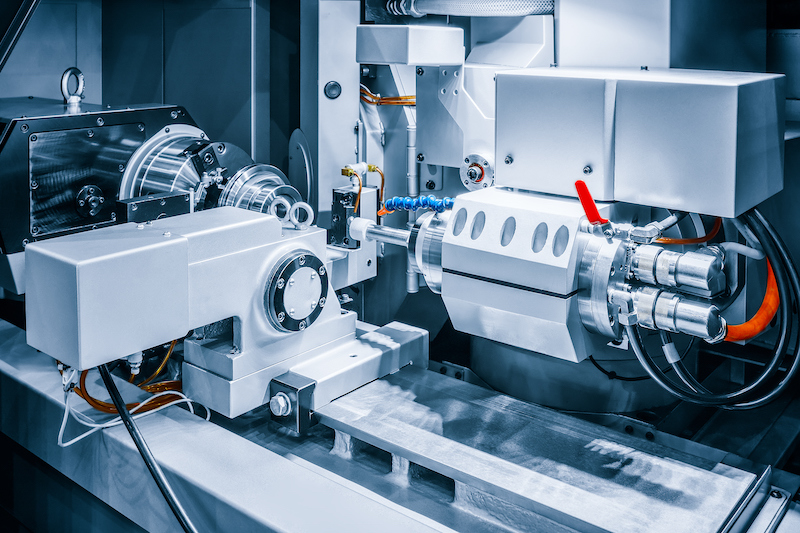

To understand the services we offer, it’s important to first grasp what CNC turning and milling actually involve. CNC turning refers to the process where a machine rotates the material while a cutting tool shapes it. This method is ideal for producing cylindrical parts, like shafts or rings, with great accuracy and smooth finishes.

On the other hand, CNC milling involves holding the material stationary while the cutting tool moves around it to remove excess material. This method allows for the production of more complex shapes and intricate designs. Milling is perfect for creating components with non-cylindrical geometry, such as gears, brackets, or enclosures. Both of these methods can be used in combination to create a wide variety of parts.

At https://radmot.com/, our facility is equipped with state-of-the-art CNC machines that allow us to provide both turning and milling services. Whether you need a simple cylindrical part or a complex multi-sided component, we have the capabilities to meet your needs with utmost precision.

Materials We Process

Our CNC services are versatile and can handle a variety of materials. The choice of material is often dictated by the specific requirements of the part being produced, such as strength, durability, weight, or conductivity. We specialize in processing metals like aluminium, steel, copper, and brass, as well as various types of plastics.

Aluminium is a popular choice because it is lightweight, corrosion-resistant, and easy to machine. It’s widely used in industries such as automotive, aerospace, and electronics. Steel is another material we frequently work with due to its strength and durability. It’s perfect for components that need to withstand heavy loads or wear over time.

For applications requiring good electrical conductivity, copper and brass are often chosen. These metals are also used in decorative or high-end products due to their aesthetic appeal. We also work with a wide range of plastics, which are ideal for applications where weight reduction, chemical resistance, or insulation is important.

Our team of experts can guide you in selecting the most suitable material for your project, ensuring the final product meets all your functional and aesthetic requirements.

Production Volumes and Cost Efficiency

One of the key advantages of choosing our CNC services is the scalability of production. While CNC machining is known for its precision and flexibility, it also becomes more cost-effective when you scale up the volume. We offer highly competitive pricing for production volumes starting from 100 units per series, with an annual volume of 1,000 units or more.

This means that for companies looking to produce medium to large batches of components, we can provide an optimal balance of quality and price. Higher production volumes allow us to spread the setup costs over more units, reducing the per-part cost while maintaining top-quality results.

Whether you are a small business looking for a reliable CNC partner for a niche product or a larger company needing mass production, we can tailor our services to match your exact requirements. Our pricing structure is transparent, and we always strive to offer the best value for your investment.

Quality Assurance and Precision

At the heart of our CNC services is a commitment to quality. Precision is crucial in CNC machining, and we take every measure to ensure that each part meets the highest standards. Our machines are equipped with advanced technology that allows for tight tolerances, ensuring that every component is made to exact specifications.

We have a rigorous quality control process that includes in-process inspections and final inspections before delivery. This ensures that every part we produce is free from defects and meets your expectations. Whether it’s a one-off prototype or a high-volume production run, you can trust that our quality standards will remain consistently high.

Additionally, our team of experienced engineers and technicians work closely with our customers throughout the entire process. From the initial design consultation to the final inspection, we ensure that all your requirements are met and that the final product is exactly what you need.

Why Choose Us for Your CNC Needs?

There are many CNC service providers out there, but what sets us apart is our dedication to providing not only high-quality parts but also exceptional customer service. We understand that every project is unique, and we take the time to understand your specific needs before beginning the machining process.

Our ability to process a wide variety of materials means that no matter what your industry or application, we can provide the right solution for you. We also prioritize communication and transparency throughout the entire process, so you are never left in the dark about the progress of your project.

Finally, our focus on cost-efficiency ensures that you are getting the best possible return on your investment. With competitive pricing, high-quality output, and a team of experts ready to assist, we are confident that our CNC services will exceed your expectations.

In conclusion, if you are looking for reliable and efficient CNC services for turning and milling, look no further. With a wide range of materials, state-of-the-art technology, and a commitment to quality, we are ready to help you bring your project to life. Whether your production needs are big or small, we are here to ensure that you get the best results every time.